Vintage News 2016

We smile in the face of adversity! – Dec 2016

Following the euphoria of finishing Thompson TK 1623, it is business as usual, with work continuing on three fronts. All three projects on which volunteers are working are in a dismantled state. All three are unique and are in a bit of a state to put it politely. It is at this stage that we hear the question, especially from disbelievers, will they ever run again? Oh they of little faith!

LNER Fish Van E75169

The outstanding welding jobs on the underframe are still not completed, though they are planned imminently. The measurements of new Sepele for the framing have been worked out and this wood is shortly to be sourced. Whilst this is a ‘fill-in’ job, nevertheless, the Fish Van is expected to see major progress in its renovation during 2017.

ECJS Restaurant Third No. 189

Carriages don’t come more skeletal than 189 is looking at present – no roof and just the framing on the sides. The defective wood on the cantrail onto which is bolted the hoopsticks (carlines) is gradually being replaced by new. The opportunity is being taken to derust the hoopsticks and fully paint them pending re-installation.

More vertical half-pillars have been inserted, replacing those considered past their sell-by-date.

Thompson CK No. 18477

18477 is parked on the concrete hard-standing outside the C&W shed and is moved into position as and when the C&W workload permits. This now derelict carriage looks a sorry sight, with most of the corridor side having been removed, exposing the compartments. Most of this side is being replaced by new hardwood. However, already, a new section of framing has been lifted into place and the transformation has begun. This section of Sepele framing had been assembled in the Atkins shed after being machined in Andrew Daniel’s Harrogate workshop. After being treated with fungicide and then by aluminium wood primer, the section was lifted out of the shed by four willing helpers after which it was raised into place using the teleporter machine. It was a doddle.

The framing, of course, sits on the top of the solebar and this had to be derusted prior to the framing being placed on top of it. Much grinding in the marsh could be heard one December weekend as this was carried out.

Beginning of a new era

In the last report, we bade farewell to Jerry Hawley, the NYMR C&W Manager without whom we would not be where we are with the LNER train. Promoted in his place has been Kieran Murray who has been with the NYMR for 15 years and, like Jerry, started as an apprentice. He is one of the really helpful paid staff members and we are really pleased he has been offered the post.

Fed up?

Fed up of household chores? Then why not have a day at Pickering in the warm ambience of the Atkins shed where you will be welcome and you will leave having helped in a meaningful way with restoring one of our carriages. Tea and cake are in abundance. Please contact Marcus Woodcock (marcus.woodcock@yorkscoast.plus.com) or Murray Brown (murraythermint@ntlworld.com) if you can come along.

The bare minimum: This is all that is left of the roof of ECJS 189 domiciled in the Atkins shed. All the roof boards have been removed because of cracking. Only then did we find that the cantrail, on top of which the metal hoopsticks are screwed, was in need of renewal. The nearest hoopstick in the picture can be seen screwed onto a new section of wood where it joins the cantrail.

It will be finished, one day, honest. Only the bravest would still be optimistic that this carriage will be restored in the fullness of time. 18477 had had a large section of its rotten framing removed, prior to brand new framing being installed. Once this has been undertaken, the next section will be similarly treated. (Murray Brown)

Transformation begins: Within hours, the new framing has been lifted into place and 18477 starts the long road to completion. (Andrew Daniel)

The top of the solebar had to be derusted prior to the new framing being installed. Christopher Johnson and Marcus Woodcock attack the surface rust. Close by Christopher’s left hand can be seen a tenon from a cross beam – this slots into the new bottom rail when it and the new framing is lifted into place. (Murray Brown)

Another historical carriage joins the LNERCA fleet – Nov 2016

It is really good to report that after an invitation and subsequent negotiation, the North Eastern Railway Coach Group which owns and is restoring the NER Open Third No. 945Y at Levisham, is to join the LNERCA as an affiliated member.

This opens the door to LNERCA volunteers helping with the renovation of this unique carriage which is being restored by a small band to a high standard. It was bought out of departmental service – DE 320716 – and came to the NYMR in July 1973. After some years stabled at Goathland, it was moved to Levisham where restoration has been on-going since the late 1990s.

The plan is to try and help the restorers as soon as is practicable. Once ECJS 189 is watertight, we plan to bring 945Y to Pickering where it can be put into the Atkins shed. First job will be to re-canvas the roof. We also intend to facilitate overhaul of the bogies – a major step forward with a view to returning this 1924 York-built carriage to working order.

All NERCG members (25 in total) will become members of the LNERCA.

This really is a significant step forward for both the NERCG and the LNERCA.

1623 – damage by passengers!

With the entry into service of Thompson TK 1623, a lull in proceedings might have been expected. Not so – ‘keep calm and carry on’ has been the order of the day. However, one surprise with No. 1623 – much admired whenever it journeys to Grosmont and back – has been the damage inflicted on the small armrests in the compartments. When 1623 was built in 1950, folk were of slim-line design, hardly surprising following war rationing. Nowadays, society has changed, especially physically, and we now have, how can this be put politely, obese passengers who cannot get out of their seats without exerting immense pressure on said armrests. The three one-inch screws which hold them to the compartment sides are clearly no longer adequate and they rapidly become loose and, in some cases the armrests have been pulled off altogether.

We have also witnessed dogs on seats – another appalling selfish act by passengers – who do not know that the moquette cost the LNERCA £9,000.

LNER Fish Van E75169

An inspection was undertaken of the Fish Van on Wednesday October 19 by the LNERCA and NYMR management – this was to ascertain just what was considered necessary in terms of finishing off welds to make the vehicle acceptable for eventual running. The contractor who had returned the van had missed several welds ands rather than have them return it was decided, thanks to the NYMR C&W manager, to employ Dave Jakeman, the C&W coded welder, to complete the job – at the expense of the LNERCA.

Also on hand was LNERCA joiner Andrew Daniel who has started measuring for the wooden framing required. This will be of Sepele.

Many photographs have been taken on E75169 when it was being stripped down, as it was known they would come in useful in the re-assembly.

A large number of removed timbers were stored in the Atkins shed so that they could be used as patterns.

We have a colleague in the timber supply business and it is anticipated that the Sepele can be obtained at advantageous rates.

ECJS Restaurant Third No. 189

Still living up to its name – ‘the coach which goes backwards’, the latest setback is the finding of some more wood rot, this time underneath where the carlines (hoopstick) bolt onto the cantrail at the top of the body. At some stage, 189 cannot go any further backwards.

Thompson CK No. 18477

Now in Pickering yard and up on jacks. This is to enable the specialist contract to attend to asbestos removal for which the LNERCA is paying the estimated £5,000 invoice. It is up on jacks to allow the main steam pipe to be dropped and removed.

Once this work has been effected, Andrew Daniel can start to prepare for the installation the new hardwood framing (already machined and stored) for the corridor side of 18477.

End of an era

Sad to report, we have bade farewell to Jerry Hawley, C&W Manager at Pickering who has left the NYMR after 32 years of service. He is joining Network Rail engineering staff at York. Jerry joined as an apprentice and worked his way up. He has always been of considerable help to the LNERCA – and the Wagon Group – and could so easily have regarded both groups as a nuisance, extraneous to the core product of overhauling and maintaining the ‘bread and butter’ Mk.1s. Instead, he not only allowed both groups to use the NYMR’s Atkins shed, but was always willing to allow his staff to help out on safety critical and other works. It is a pleasure to acknowledge his support to us over many years.

Fancy that?

If you fancy lending a hand for a day to see if you enjoy it, then please contact Marcus Woodcock (marcus.woodcock@yorkscoast.plus.com) or Murray Brown (murraythermint@ntlworld.com).

The LNERCA welcomes North Eastern Railway Third Open 945Y and its members, the NER Coach Group, to the fold. The exciting prospect of advancing 945Y’s restoration to the point of it entering traffic has taken a step nearer as the LNERCA volunteers will be able to help re-canvas the roof, overhaul the bogies and replace the gangway bellows. It initially was built in varnished teak but was soon adorned in NER crimson. This view was taken at Levisham nearly 20 years ago – since then this unique survivor has been hidden away under a tarpaulin. (David Idle)

Jerry Hawley (left) C&W manager at Pickering, is departing for pastures new. Undoubtedly, his encouragement to help at all times and for the facility of the Atkins shed has allowed the LNERCA to make substantial progress, especially with Thompson TK 1623 which was moved into the Atkins shed on the building’s official opening. He is pictured with the LNERCA’s joiner, Andrew Daniel.

New to Pickering yard is the derelict 1950-built Thompson Composite Corridor (CK) No. 18477. It has not carried passengers since 1972 and was one of the earliest carriages to come to the nascent NYMR in 1969. Its presence in the yard is to allow a specialist contractor to remove any remaining asbestos insulation prior to woodwork repairs starting. This view of the compartment side shows the damaged plywood paneling – this was applied in the 1970s by the York Area Group when the carriage was taken out of traffic. (David Young

The corridor side of 18477 – enough to daunt any budding LNER carriage restorer. However, it does not daunt the LNERCA’s joiner who has prepared the replacement hardwood framing for this side of the carriage. After this side has been renewed, the carriage will be tarpaulined over and stored pending raising of funds for the next stage of restoration. 18477 was one of the last Thompson-designed passenger carrying carriages to be condemned, this taking place at York on September 21, 1968. It arrived on the NYMR in June the following year. (David Young)

Edward Thompson’s descendant declares 1623 ‘open for passengers’ – Oct 2016

September 24 – the culmination of over 20 years’ restoration. Two return trips using the LNER set including TK 1623 was made – the first time an eight-coach LNERCA set had run on the NYMR. The event was a ‘thank-you’ for all the restorers, and their families to see and enjoy a ride with the unique completed Third Corridor.

We had to agree that the first run, the 11.00 service from Pickering, would be the normal service train because had we taken the empty 10.00 path, the NYMR, apparently, would have had to cancel the 11.00 service because there were insufficient carriages.

The 12.30 from Grosmont and 14.00 ex Pickering, however, were special to LNERCA members and also the Thompson B1 Locomotive Society members. They had provided their B1 61264 – such an appropriate locomotive for the occasion. It carried the headboard ‘The Thompson Renaissance’. On arrival at Pickering, LNERCA Chairman Nick Stringer welcomed everyone to the event, whilst Vice Chairman Murray Brown thanked everyone for their support in so many ways. He singled out Jerry Hawley and two of his paid staff, Keiran Murray and Gordon Neale for all their assistance, the PRISM Fund which got the restoration off to a good start with the first installment of £2,000 (in total £20K), Master painter Dave Simpson from the SRPS, Bo’ness’, who undertook the much admired scumbling, The Thompson B1 Locomotive Society for supplying the locomotive and LNERCA joiner, Andrew Daniel for undertaking such a complex job as renewing the complete bottom rail whilst the roof was still in position – believed to be a ‘first’ in preservation circles. Andrew had also replaced a missing compartment partition in addition to helping throughout its restoration. Murray Brown then handed over to the special guest who announced just who he was – Edward Thompson’s great nephew, Tom Walters.

Mr Walters was delighted to be asked to attend and recalled his Great Uncle when Tom Walters was a young boy, calling him ‘Uncle Ned’. Mr Walters was then invited to cut a ribbon on one of the doors of 1623 to officially declare it ‘open’. Mark O’Brien, NYMR boiler Inspector and Engineer of the TB1LS, had arranged a cab ride for Mr Walters – the first time he had ever had one.

A sumptuous buffet had been provided for £10 per head but some folk chose not to know the price and expected it for free. It had been widely publicised that a £10 donation would be appropriate. The buffet had been prepared by Maureen Skelton and her friends, Jim Kay and Edwin Craggs – it was much appreciated by everyone, whilst Andy Furness manned the bar.

A particular fitting and nice touch was the provision of specially made destination boards ‘King’s Cross – Whitby’. Few people were ‘in the know’ about this, the idea being it would be a pleasant surprise – it was. Thompson carriages were often used as the through carriage on King’s Cross services, coming down to York on ‘The Scarborough Flyer’ then being shunted onto a Whitby-bound service. LNERCA Archivist, John Sutcliffe, deserves commendation for this initiative on the day.

It was a superb occasion and a fitting and rightful culmination to so many years’ hard slog. The Trust Chairman attended, as did Tom Bright from ‘Steam Railway’ magazine.

The local media in general showed no interest – a considerable disappointment.

LNER Fish Van E75169

The Fish Van is home! It arrived on a transporter at New Bridge on Tuesday September 27th and was unloaded the same morning. In the afternoon, the C&W Class 08 shunter came to collect it and took it to Pickering yard. The following day, it was craned onto its temporary isolated piece of track alongside the LNERCA’s workshop where it will now be rebuilt.

Andrew Daniel will be in charge of the woodwork necessary. An inspection of the NRM’s ‘Blue Spot’ fish van took place place on October 7. For this we are grateful to Curator Bob Gwynne. The inspection revealed that there are considerable differences between the later roller-bearing variation (diagram 800) and the earlier LNER design (ours) – diagram 214.

Much of the old woodwork from 75169 was retained as patterns.

Work will now progress at the same time as work on ECJS 189

East Coast Joint Stock Restaurant Third No. 189

Marcus Woodcock has continued replacing defective half pillars along the bodyside. The old ones are sawn out and the new ones carefully cut to size, then glued and screwed into position.

Meanwhile, along both sides of the clerestory roof, all the maroon paint and sealant is being removed, together with prising out the scores of tacks which held the clerestory roof canvas in position.

Yet another setback has taken place, further justifying the epithet of ‘the coach which goes backwards’. A patch of rot has been found under most of the steel carline ends on the clerestory roof and all the steel screws holding the carline down are badly corroded. (The carline is sometimes called a hoopstick, which spans from one side pf the coach body to the other, and onto which the roof boards are bolted). The easiest way to remedy this will be to remove the carline, splice in a new timber pad under the ends and re-screw down. This of course means removal of the roof boards, this is not too much of a disaster as because we have already taken the decision to replace the centre roof board to help support the light fittings, so most of the boards will have to be removed anyway.

LNER Composite Corridor (CK) No. 18477.

We await 18477 being shunted into Pickering yard where contractors will remove residual asbestos insulation. When this is complete, Andrew Daniel will then fit the new framing to the corridor side. 18477 will then be shunted back into the Long Siding pending raising of funds for the next stage of its restoration.

Appealing appeal

Do come along for a few hours to lend a hand and to see if you enjoy it – it really is most rewarding to help restore a carriage – something to see at the end of it.

Any enquiries – please contact Marcus Woodcock (marcus.woodcock@yorkscoast.plus.com) or Murray Brown (murraythermint@ntlworld.com).

Meet Tom Walters – Edward Thompson’s great nephew. He was most pleased to be invited to the launch event and during the speeches recalled meeting his great Uncle who gave him half a crown – a large amount of money in the early 1950s.

Tom Walters cuts the ribbon on, the door of 1623 to declare the carriage ‘open for passengers’. Mr Walters was then given a cab ride on No. 61264 thanks to the Engineer of the Thompson B1 Locomotive Society, Mark O’Brien (Image: Malcolm Brown).

A close-up of the destination board, with one on each side. 1623 is the only carriage in the LNER set to carry destination boards and it has been suggested that all our carriages are so fitted, either with ‘LNER Coach Association’ or ‘Pickering – Grosmont’. In the 1950s, there was a through coach working from London which was transferred from ‘The Scarborough Flyer’ at York onto a Whitby-bound service. Often, this was a Thompson-designed carriage (Image: Malcolm Brown).

To mark the entry into service of TK 1623 and also the return to service of Thompson B1 61264 after 18 months under repair, the special train carried the highly appropriate headboard ‘The Thompson Renaissance’. It is pictured at Grosmont prior to the departure of the 12.30 special. The headboard is now on display inside the Atkins shed at Pickering. It will come out again when CK 18477 is restored – a few years hence!

After its shotblasting, welding and painting at DC Engineering, Shildon, the unique Fish Van arrives back on the NYMR, seen here on the transporter at New Bridge yard, about to be unloaded.

The van, E75169, was then shunted into Pickering yard by the Class 08 shunter, 08850, and then the crane took over. The van is hoisted off the turntable onto its isolated piece of track. (Image: Malcolm Brown)

The van has landed. Its new home for quite a time – outside the LNERCA’s workshop at High Mill, Pickering. The body will now be rebuilt. (Image: Malcolm Brown)

A surreal launch into traffic – Sept 2016

Thompson Third Corridor (TK) 1623

Dateline: Thursday September 8, 11.00 hrs.

After C&W fitter, Kieran Murray shunted TK 1623 into the LNER set, the long restoration was over and this Thompson-designed carriage set sail with its first fare-paying passengers since September 1968. It was surreal. Many of the regular volunteers were on board to savour this occasion – a just reward for their years of toil.

Even up to the entry into service, TK 1623 was trying to scupper its own launch. Indeed, it had been suggested in the latter months of restoration that we had already embarked on its overhaul even before it had entered service. The north end toilet cistern plagued all attempts to make it leak-free. One day it would work fine, then the next, the handle would not rise automatically once depressed and thus continue to let water drain through. Every time, this meant dismantling the cistern to investigate and remedy possible defects. Every time it was removed and taken to bits, this ruined the primrose paintwork on the huge locking nuts and drop pipe to the bowl and had to be done again once the cistern was back in place.

The purpose of it entering service was to give it time to sort out any possible gremlins prior to the official launch, scheduled on Saturday September 24. On this day, the LNER set will make two return trips to Grosmont at 11.00 and 14.00, returning at 12.30 and 15.40. Everyone associated with 1623’s restoration is invited to attend – tickets are free – but must be obtained in advance – please contact Murray Brown (murraythemint@ntlwotld.com)

After arrival at Pickering at 13.40, a special ‘celebrity’ will officially cut the ribbon to declare 1623 ‘open for business’.

East Coast Joint Stock Restaurant Third No. 189

“Will this carriage ever stop going backwards?” was the riposte of a volunteer – perhaps with some reason when you look at the skeletal remains. We think we have found all there is to find in the way of defects and suspect repairs – and the only way is up.

During the ‘Coach Week’ a huge amount of energy was expended on removing – and trying to remove – as many of the screws from the hoopsticks, the metal ‘arches’ which span from one side of the body to the other, onto which the roof boards are screwed. The ones being removed are screwed in upwards in the channel hoopsticks. Some screws come out without any effort, others are seized solid and require hammers, chisels, gas flame and other impliments of destruction.

Once the screws are removed, a hole is drilled from the hoopstick hole, through the wooden roof board and then a stainless steel bolt is fitted and nutted up from underneath. This is our standard practice for securing roof boards and provides far more rigidity.

As part of the process, much of the old sealant was sanded off the roof to give a smooth surface for the canvas when finally fitted. This produced, as can be imagined, vast amounts of yellow dust.

LNER Fish Van E75169

We were all set to welcome the Fish Van back from Shildon on Tuesday September 6 when, due to an inability to secure a transporter with steerable wheels, the move was cancelled.

The plan is now to drop the Fish Van off a standard transporter at New Bridge yard and shunt it up to Pickering. It will be parked outside the LNERCA workshop at High Mill crossing.

LNER Composite Corridor (CK) No. 18477.

This is our next major restoration project following ECJS 189. Already a large amount of new framing has been machined ready for fitting to the corridor side of this 1950-built CK – a sister carriage to TK 1623.

Prior to this work taking place, all the seats were removed and placed in Thompson BG E110, our stores carriage, and another product of Edward Thompson.

This is to allow access to the ‘heritage insulation’ (asbestos to you and me) for which a quote has been obtained for its removal by a professional removal company. This includes the insulation beneath the steam heaters, behind radiators, and the main steam pipe underneath. The LNERCA is footing the bill for this work for which funding is to hand.

A veritable treasure trove of historical junk was found when the seats were removed, these including sweet packets dating from pre-decimal days (LSD), a First Class hand-written ticket from King’s Cross (so at last we have proof 18477 did work into the ‘Cross’ but it was almost inevitable it did on hundreds of occasions) and, would you believe, a Family Planning leaflet. These are temporarily on show in the display cabinet in the Atkins building.

Please help

We welcome anyone who would like to get involved. All types of disciplines are there to be enjoyed – woodworking, metalworking, electrical, painting. Only requirement is a sense of humour and a mug. Please contact Marcus Woodcock (marcus.woodcock@yorkscoast.plus.com) or Murray Brown (murraythermint@ntlworld.com) if you fancy helping.

September 8, 11.00. TK No. 1623 waits to leave with its first run in passenger service, carrying fare-paying passengers for the first time since 1968. Many of the restorers thought this day would never come. The opportunity to take part in a little part of the LNERCA’s history could not be missed and here a group of volunteers, who spend their life in the Atkins shed, take a break and pose for posterity before enjoying 1623’s first run. (Sonia Brown)

Frame repairs continue on No. 189. An example of the outstanding quality of repair can be seen here with a new piece of teak spliced into the waist rail half-way up the bodyside. Once the defective wood is cut out, the new piece is glued and screwed into place.

A recent volunteer who has joined us is Neil Cawthorne. He is an expert in picture framing and the application of gold leaf. He is pictured meticulously sanding away residual varnish from the pantry door of ECJS Restaurant Third No. 189.

Long-standing volunteer stalwart, Doreen Williams, removes paint and filler from the wooden strip which holds the edge of the canvas in place at the top of the bodyside. One perk of this job is that it can be accomplished outside where Doreen can wave to passing trains.

After some 20 years of restoring TK 1623 to original as-built condition and spending some £100,000 in the process, you can imagine the Association’s despair when the NYMR applied the hideous flourescent yellow stripes on the insides of the doors. This practice was instigated so that platform staff could see easily if doors were not correctly shut. The platform staff should really be looking at the door handles. Of interest is that a former ORR Inspector told volunteers at another heritage railway that the practice of applying yellow stripes on doors at the NYMR was “over the top”. The LNERCA has raised the topic with the General Manager in the hope that a derogation might be given in view of the historical nature of the carriage and the fact it does not work over Network Rail metals to Whitby.

We have been donated doors and compartment sides from what was a North Eastern Railway coach body from Tollerton, north of York – stored in a field. This view shows them laid out outside our High Mill workshop at Pickering – and gives some insight into what the coach looked like. We do not know any more details – type of carriage, nor number. Whilst we may not have a direct need for all these items, it is likely that the Tanfield Railway might well be interested, as that heritage railway possesses various NER carriages.

Roger Melton has procured replica brass gasolier fittings, the idea being to use these, but with L.E.D lights as we suspect the Health & Safety police would preclude us from using gas as originally lit the carriage! There is one slight problem – they weigh a surprising amount, resulting in considerable debate as to how they could be suspended from the roof and whether the roof needs supporting. Pictured laid out on a table is one set of fittings.

Thoughts are now turning to another project, with the completion of Thompson TK 1623. Whilst ECJS Restaurant Third No. 189 (in the Atkins shed) is now the main focus of attention, some work will soon start on replacing the corridor side framing on Thompson CK (Composite Corridor) No. 18477. This carriage has not turned a wheel since 1972 and is, bluntly, in a bit of a state understandably. A start was made during the recent ‘Coach Week’ to remove all the seat cushions and backs – this is to allow access by contractors to remove any residual asbestos insulation. In this picture, the somewhat derelict compartment can be seen – a few hours work needed here! The seats were removed for storage in Thompson BG No. 110 which is to be used as a central store for all parts removed from 18477 – this will make the job of finding them, when needed, so much easier than was the case with No. 1623. (Malcolm Brown)

This view shows the parlous state of the corridor side framing on 18477. The green on show is the tarpaulin sheet which is covering the whole vehicle, the side panelling having long since been removed. All this framing is to be renewed and brand new teak sections have been machined by Andrew Daniel and are awaiting fitting as soon as No. 18477 can be moved into Pickering yard for access. Once this work has been completed, the carriage will be sheeted over pending the raising of further funding to undertake the next stage in its restoration. (Malcolm Brown)

Ready for service – unbelievable! – Aug 2016

Thompson Third Corridor (TK) 1623

The long wait is over. After nearly twenty years of restoration, TK 1623 awaits entry to service.

A test run to Levisham, in the company of Pullman Car No. 79, revealed no obvious defects apart from a niggling flat wheel – the C&W Manager, Jerry Hawley, thought this was in the root of the tyre – it was noticeable going round a left land corner – and proffered the view that the ‘flat’ would probably wear itself out in time.

The final jobs carried out in early August included completion of the buckeye couplings and their chains, checking the ride height, painting the south end toilet cistern and drop pipe, adjusting the brakes and fitting a dynamo belt.

This brake adjusting was accomplished by shunting 1623 to New Bridge where it was put over the locomotive pit to allow easy access.

Jerry Hawley felt the best date for 1623 to enter public service would be to wait until the start of the red timetable on September 5. This would still give enough time to find any problems prior to the carriage’s official launch on September 24 and would reduce the time it was getting dirty and letting the public loose in its pristine condition!

September 24 will see the first eight-carriage LNER set to run on the NYMR. The set will form the 11.00 service from Pickering. At Grosmont, it will form a special 12.30 to Pickering and 14.00 return for LNERCA members and guests, together with the Thompson B1 Locomotive Society members. This group is supplying, appropriately for the occasion, No. 61264. The train will carry a headboard ‘The Thompson Renaissance’.

On arrival at Pickering at 13.40 a rather special railway guest will perform the honours of declaring No. 1623 ‘open’ and cut the ribbon. The final run of the day of the set will be the 15.40 service train from Grosmont to Pickering.

All LNERCA and TB1LS members are invited to ride on the special – tickets are free and are available from Nick Stringer and Murray Brown

Please help

We offer a warm welcome to anyone who would like to come along and lend a hand. There is interesting work for all tastes and skills. The Atkins shed next to Pickering station car park is open most days – do email Marcus Woodcock (marcus.woodcock@yorkscoast.plus.com) or Murray Brown (murraythermint@ntlworld.com) if you fancy helping.

On July 27, 1623 made a test run from Pickering to Levisham to ‘bounce the springs’ and see if all was well. It was, apart from an annoying wheelflat. Here the Thompson has escaped from Pickering after many years domiciled at Pickering – it was in the company of Car No. 79 which was also being tested following wheelset replacement. Picture: Simon Barraclough.

All the compartment shoulder lights have now been fitted – and look tremendous. A trial fitting of a L.E.D. lamp was a revelation in terms of brightness and the go-ahead has been given for all the bulbs to be L.E.D. type. Of interest is that this will reduce the power consumption from 25 Amps to 4 Amps.

C&W fitter, Keiran Murray has been one of the helpful full time staff who has assisted in the final completion of 1623. Here he is fitting the safety chain to the recently installed buckeye coupling. The buckeyes are sent away to a Leeds firm for machining and incorporating the lower shelf bracket at the rear of the coupling. These help stop over-riding in the event of a collision.

Probably for the first time in its 66-year life, 1623 enjoys top and tailed Class 08 traction. This took place on August 11 when it was tripped to New Bridge p.way yard for access to the loco pit where brake adjustments were finalised. Picture: Marcus Woodcock.

Whilst Gresley Brake Third Corridor 3669 has been parked in Pickering yard, the opportunity has been taken to make some finishing touches – these being the fitting of blinds to the compartment windows. A firm at Starbeck, Harrogate, specially made these blinds.

1623 – it’s looking good! – July 2016

Thompson Third Corridor (TK) 1623

The long restoration – over two decades, but not continuously – is tottering towards completion. The final few outstanding jobs are in hand, with a view to allowing the 66-year old carriage into service.

A small leak on the south end toilet cistern is receiving attention.

All the seats are now in place with armrests duly fitted.

Our ‘Master Scumbler’ Dave Simpson from the SRPS returned to Pickering to rescumble the damaged vertical panel. For this Jerry Hawley agreed 1623 could go under cover to allow the various coats to dry. It is planned to apply two more coats of varnish.

Furniture for both toilets is now in place – the grab handle and the towel rack.

Internal transfers for the doors (don’t lean out etc) and above the communication chain (pull it at your peril – £5 etc) are in the process of being applied.

One compartment is fully fitted out with shoulder lights and, when switched on, look tremendous. We could write a book on how we could never see a light at the end of this particular tunnel. It may well be that a shoulder light might be the very last item to be ceremonially fitted and switched on to declare the carriage finished.

In preparation for its entry into service a thorough spring clean has started.

On July 15 C&W fitter, Keiran Murray began fitting the Buckeye couplings. A test run to New Bridge and back is planned in the next few days to bounce the springs and allow another check of the ride height.

East Coast Joint Stock RTO No. 189

Following the decision to renew the clerestory roof boards, a start has been made on removing the scores of screws which hold the boards onto the carlines (hoopsticks) and wooden formers. This is a long job, most rusty screws refusing to budge and only coming out after a battle, accompanied by quantities of dust and rust.

When the new boards are in place, instead of screws, nut and bolts will be inserted, this being our normal procedure for securing roof boards in place.

Further varnish stripping and replacing of lower half pillars also continues in between work to finish 1623.

LNER Fish Van E75169

Arrangements are now in hand to return E75169 to Pickering. On its arrival, a detailed inspection and plan will be formulated to procure and then make the necessary framing. Many of the original components were retained so that they can be used as patterns.

It is highly unlikely that insulation will be fitted in view that E75169 must have carried its last fish – unless we mark its completion by conveying a ceremonial box of kippers.

A request has been made to the National Railway Museum to allow access to their Fish Van so that measurements can be taken. The NRM’s vehicle is a later BR build (‘Blue Spot’) which to all intents was the identical vehicle to ours, except the NRM van has roller bearings.

Do help us

We welcome your support. If you are interested in what we do and wish to see more LNER vehicles return to service, we welcome offers of assistance. This can be by attending where plenty of jobs to suit all tastes can be found. Alternatively, a handsome cheque always helps – it costs a fortune to restore these beautiful carriages, so every penny helps.

If you would like to lend a hand, do please contact Marcus Woodcock – marcus.woodcock@yorkscoast.plus.com These are the remaining dates in July when he will be present to offer a welcome, cup of tea and cake and a rewarding job for you.

Sat 16th – Working weekend

Sun 17th – Working weekend

Thurs 21st – Working weekend

Sun 24th – Working weekend

Thurs 28th – Working weekend

Sun 31st – Working weekend

Once 1623 is completed, work can concentrate on East Coast Joint Stock No. 189 and if the weather is good a few days on the rapidly disintegrating workshop.

The signs are looking optimistic that TK No. 1623 will be well and truly finished after over two decades of work. One of the signs of the impending completion is the fitting and application of the internal signs. The ‘No-Smoking’ was specially applied by a signwriter from York. (Pictures: Adrian Scales)

The first compartment has been fitted out with all four shoulder lights, the culmination of months of efforts, with no less than 5 manufacturers specially producing the components, with a sixth providing the pygmy bulbs.

Another carriage for LNERCA fleet – May 2016

NER Luggage Composite No. 1111 joins the collection

In a surprise development, the NER Coach Group has donated its North Eastern Railway No. 1111 to the LNER Coach Association. The carriage has been based at Levisham since its purchase from BR in 1973 and is used by the Levisham Station Group. This practice will continue. When built, it was a 6-wheeled carriage, however, the middle wheelset was removed when in departmental service and was in this condition when bought by the NERCG.

Built at York, the coach dates from 1890 and so becomes the oldest in our collection. It was withdrawn in 1924 to become a Tool Van for which it was placed in the departmental series as DE 900192.

Thompson Third Corridor (TK) 1623

The main steam pipe has been lagged whilst the carriage was on jacks outside the C&W workshop – it was lowered back onto its bogies on Tuesday April 24. Some re-bushing of the brake rods were undertaken first by Gordon Neale of the C&W staff.

In another development, a semi-circle piece of scumbled paintwork has lifted from one of the vertical panels between the windows. This is thought to be the location where a metal plate had been welded over a vent (put in in departmental days). This had then been filled to quite a depth before scumbling was applied. Dave Simpson from SRPS, Bo’ness’ who undertook the original scumbling, has paid a visit to inspect and advise on its repair. He is likely to be visiting again to apply new scumbling once the repair has been effected. For this, 1623 will need to be under cover.

The revarnished end doors which were damaged by water ingress due to the carriage not being fitted with protecting gangway ends have been lifted back into the carriage for refitting. This was another of those annoying jobs which had to be undertaken twice – inviting the wags to comment that we were already overhauling the carriage before it even entered service.

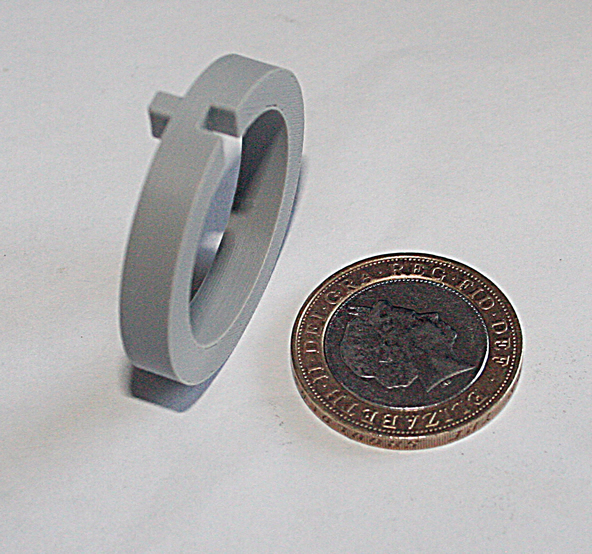

The final piece of the interminable ‘jigsaw’ of the compartment shoulder lights is now in hand – the manufacture of a spacer ring. This is being done using 3D Print technology. Mr Edward Thompson would be amazed if he was still around – manufacture of components using computer technology. These will then be painted ‘Bakelite’ brown as per the cover switches. Matching paint has already been sourced. This will then allow the final assembly of all 28 shoulder lights. This really has been a never-ending round of procurement problems as the whole assembly has had to be made – ‘Bakelite’ cover, the toggle switch, brass retaining ring, LNER-design lampshade and, finally, this spacer washer. Oh, yes, don’t forget the pygmy bulbs as the ordinary 24v bulbs would not fit!

Finally, for the first time since October 1967, 1623 has two working toilets. The north end toilet plumbing has been completed and the loo was ceremonially flushed to mark the occasion. This took place on Sunday May 22.

East Coast Joint Stock RTO No. 189

Varnish stripping has continued – in affect, the entire varnish on the whole carriage is slowly being stripped to bare wood in order to start afresh. In many cases, it had ‘blown’ or flaked off.

All the knee-irons (right-angled brackets) bolted to the framing have been removed. These have been de-rusted, painted with green anti-oxide paint, undercoated and top coated in black. A start has been made in refitting them to the framing using zinc-coated coach bolts.

LNER Fish Van E75169

With work now completed at Shildon, just the final signing off needs effecting before the unique van can be returned to Pickering where thoughts will turn to making new Sapele framing and repairs to the roof..

After a cosseted sojourn in the National Railway Museum after partaking the Flying Scotsman exhibition, BTK 3669 is coming back to the NYMR to enter public service again. Perhaps the one disappointment was the lack of publicity for the LNERCA for loaning the carriage. (Photo: Terry Bye, Pullman Car Services)

Whilst TK 1623 was up on the jacks having its main steam pipe fitted, its bogies were prepared for the carriage to be lowered. Some rebushing of the brake rodding was needed, seen here being undertaken by C&W fitter, Gordon Neale.

With the main steam pipe fabricated in sections and fitted, it was then lagged, this time with modern heritage insulation!

More tell-tale evidence of 1623’s impending completion is the addition of lettering on the solebar and inside the carriage. For this a specialist was brought in. ‘V’ denotes the varnishing date and the other date refers to the lift.

Here is the finished spacer washer, made by 3D Printing. These are for use on each of the compartment shoulder lights, so 30 have been made (28 plus 2 spares). They have been since painted ‘Bakelite’ Brown to match the cover. The 3D Printing entails building up fine layers of a polymer which is instantly dried and sealed by a light source. The machine lays down the polymer layer in accordance with the specialist computer drawing which is the first part of the process.

This graphic illustration shows just why so many half-pillars (the vertical struts from the waist rail to the bottom rail need replacing with new. This example is by far the worst of the lot!

A ‘Forth Bridge’ job on the East Coast Joint Stock Restaurant Car No. 189 is the removal of varnish down to bare wood. Weilding the hot-air gun is Andy Furness.

With the removal of the canvas from the clerestory section, more woodwork was revealed to be in need of renewal. Three LNERCA volunteers are removing various sections and replacing the clerestory formers (the supports which hold it up). (Photo: Malcolm Brown)

For the first time, it has been possible to photograph TK 1623 in the sunshine devoid of all obstructions. As can be seen, the much maligned Edward Thompson certainly designed a good looking carriage.

Because a semi-circle section of scumbling has ‘lifted’ away from the bodyside, probably due to sitting in scorching heat, it was necessary to go back to bare metal and fill the void. The bodyside panelling was slightly distored originally because BR had inserted a vent which was subsequently plated over – in the process, this resulted in an uneven surface, necessitating filler to even out the panelling. Our expert ‘Scumbler’, Dave Simpson from the Scottish Railway Preservation Society, Bo’ness, has been advising in the repair and will be revisiting Pickering to provide the new layer of scumble paint. In this view, Marcus Woodcock is applying the new filler.

With the roof boards having numerous splits, it has been decided to replace them all, rather than change the odd one. This latter course of action would only have resulted in having to give remedial attention to the roof in a few years time, whereas replacing the lot in one go will ensure the roof lasts half a century provided there is no water ingress. Another factor in the decision is that all the steel screws holding the roof boards to the carlines are rusted and many have lost their ‘bite’.

Whilst all the work has been in progress on TK 1623 and RTO 189, the C&W staff have been busy inside Gresley Buffet 641. A new oven and vent hood has been fitted – these are all part of conforming to gas regulations. In addition, the internal saloon has been given a spruce-up. Its first use was on the inaugural, highly successful, Curry Train which ran on May 6th. The whole LNER set is likely to see more use on these evening dining trips.

Fish Van re-assembly underway – April 2016

LNER Fish Van E75169

DC Engineering, Shildon, has begun re-assembling the structural metalwork on the Fish Van frame. This follows considerable attention to the frame, headstocks and side members.

Erection of the vertical stanchions is also in hand and the plan is to complete this metalwork to the stage where it is stable and complete – enough to be transported to Pickering, once space is available outside the LNERCA’s workshop.

Once returned to Pickering, all the woodwork will be re-instated – this comprising the new roof boards, the framing for the ends, followed by the fitting of the block board all round. The latter is already in stock.

Whilst the restoration of this van may be dismissed as irrelevant, its return to pristine condition is of considerable importance – it is the sole, surviving complete LNER Fish Van – and is highly relevant and historically important to the NYMR in that this type of van regularly worked over what is now the Moors Railway. Indeed, with its withdrawal date, there is a high degree of certainty that our van was one of the last to leave the East Coast resort of Whitby, their final use being in the early 1960s.

It is also of little known fact that E75169 is the second of the LNERCA’s fleet to be shown as being broken up after withdrawal, in this case in Doncaster Works in 1972. Whereas it obviously survived. It became an Internal User vehicle at the Works until being bought by a member of the Nene Valley Railway from whom the LNERCA bought it in 2008.

Thompson Third Corridor (TK) 1623

After the first successful steam test on March 30, the remaining leaks have been eliminated. There is further work to begin on fitting the insulation to the main steam pipe. This will entail the carriage being lifted once again – it was temporarily re-united with its bogies as another vehicle was required to be stabled on the concrete apron outside the C&W shed.

East Coast Joint Stock RTO No. 189

Current work is seeing continuing replacement of the small bottom bodyside pillars and, on the roof, refitting of the metal carlines onto which will be fastened the new roof boards in due course.

The reborn Fish Van begins to take shape at Shildon on April 8. The van will be completed at Shildon structurally, leaving all the woodwork to be fitted at Pickering. (Photo. Nick Stringer)

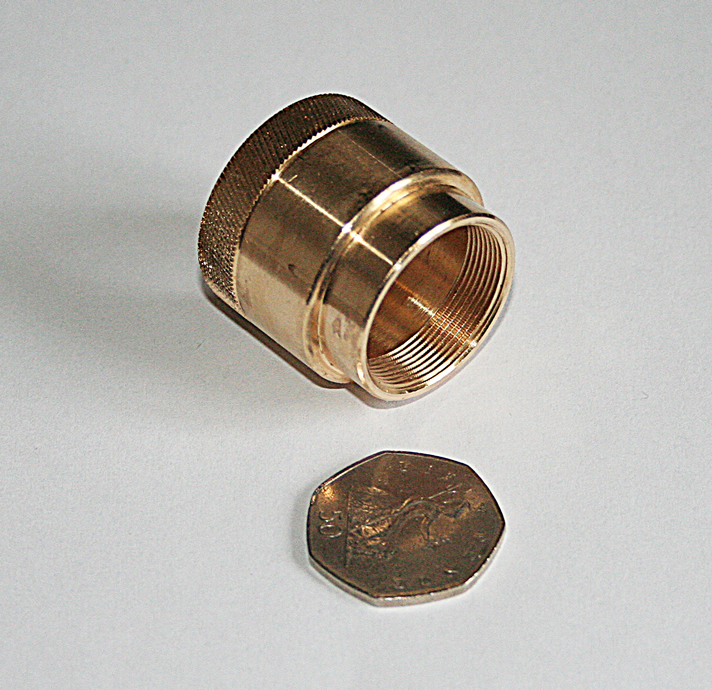

This is the specially made brass retaining ring, manufactured by S Lilley Ltd, Birmingham, which holds the compartment lampshade onto the toggle switch. The standard fitting would not suffice, hence a special order. British Rail, by throwing out all the compartment shoulder lights when it converted the carriage for departmental use, has caused us a vast amount of effort and money – we have had to have specially made the toggle switch itself, the ‘bakelite’ cover, the lampshade and the retaining ring – all times 30. On top of that has come the bill for 30 Pygmy bulbs. Is there a moral to this story?

Whilst not LNERCA News, the appearance of a LNER Gresley in King’s Cross is – and our colleagues on the Severn Valley achieved that accolade on April 5th when their Kitchen Composite No. 7960 was on show, together with the Gresley Society’s N2. It was part of the event marking the unveiling of Sir Nigel Gresley’s statue in the adjoining concourse. We hasten to point out that we, too, have had a Gresley carriage on Network Rail this year – No. 3669 passed through York station whilst en route to the NRM to take part in the Service with Style exhibition!

STOP PRESS! – March 2016

An important milestone was reached with the restoration of Thompson Third Corridor (TK) 1623 at 16.00 on Wednesday March 30 when steam was piped through the carriage for the first time since this carriage was withdrawn from passenger-carrying service in 1968. It was a trial to test the newly fabricated main steam pipe which had been connected to all the compartments. ‘Black Five’ 45428 officiated, thanks to driver Matt Fisher who came into the carriage shed to witness history being made. The C&W has several lengths of steam pipe which can be joined and run out of the shed and coupled to a parked locomotive beside the water column. The other end, of course, is connected to the carriage – 1623. Amid a smell of hot paint, the trial was a success, with only two small steam leaks to eradicate at a later date.

East Coast Joint Stock Restaurant Third No. 189

What is hoped will be the last major woodwork repair has been completed – the machining and installation of a 15ft section of lower clerestory cant rail. With this now in place, work has started in refitting the refurbished formers which link the bodyside with the clerestory section and on top of which are fitted the roof boards.

Further down the body, refurbished brackets – knee irons – are being bolted into place using stainless steel bolts.

Thompson Third Corridor (TK) 1623

This carriage has been moved into the C&W workshop to enable the gangway ends to be lifted into place (now effected) and the installation of the main steam pipe underneath. This has to be fabricated in sections because it does not follow a straight line underneath the carriage but weaves around to avoid obstacles. Hence a section at a time is cut, threaded and then lifted up to be fitted to the retaining brackets. T-sections are used to fit the steam ‘dropper’ pipes which descend from the compartments and which are fitted to the main steam pipe.

One of the gangway ends needs further attention to straighten it – much work had already been undertaken to achieve a flat edge – this buts up against the adjacent carriage to which it is coupled.

S Lilley & Son Ltd, Birmingham, has agreed to make the special brass retaining rings which hold the new lampshades onto the toggle switch in the compartments.

The end is now really in sight to complete the restoration of this unique carriage. A possible official launch date in September is being considered, although 1623 should enter public service before then without ceremony.

LNER Fish Van E75169

Re-assembly of the body frame is now underway at DC Engineering, Shildon. There is no immediacy for the Fish Van to be returned to Pickering.

LNER BTK No. 3669

Now on show at the National Railway Museum with the Flying Scotsman exhibition. One final component is being made – blinds for the windows. The prototype, like the rest of the carriage, is exemplary.

Illustrating the quality of the restoration in ECJS 189 is this view of the long section of lower clerestory rail. With this now in place, refitting of the roof formers is now taking place.

The pantry has been dismantled in order to repair defective wood. The new lower clerestory rail is above the camera and the roof formers, (two can be seen on the right hand side) will now be refitted, allowing the new roof boards to be screwed into place.

At the lower end of the body, right-angled brackets which have been derusted, primed, undercoated and top coated are being fitted using stainless steel bolts. Work is continuing on replacing the vertical small pillars if condition necessitates this.

Looking like a carriage again for the first time since 1967 is this view showing the gangway end in place. BR used to remove the gangway ends when carriages were converted for departmental use, i.e. for instance with the Civil Engineer as a Mess Coach, as befell 1623. It was renumbered DE 321133 for its new role.

It’s unusual to see both roads in the Pickering C&W occupied by LNER carriages. On the left is Thompson TK 1623 whilst on the right is Gresley Buffet 641 having its kitchen equipment upgraded, as well as an internal spruce-up.

Now starring at a Museum near you! BTK 3669 takes pride of place in the Great Hall of the National Railway Museum as part of the Flying Scotsman exhibition. The invitation to partake in this event is a fitting testimony to the superb quality of its restoration. The view through a Channel Tunnel segment shows 3669 in the middle of three carriages. Nearest the camera is 1898-built ECJS Third Corridor No. 12, whilst nearest the turntable is 1948-built Thompson Lounge Buffet 1706. (Photo: Nick Stringer)

East Coast Joint Stock Restaurant Third No. 189

Replacing defective and split lower pillars continues. The hardwood replacements were machined in advance at Andrew Daniels’ workshop.

Meanwhile, higher up, part of the defective cant rail has been chiseled out and new sections spliced in.

Further areas of varnish have been removed down to bare wood – these include the bottom rail, on both sides, and some end panels. Once the initial varnish has been removed, further work is required to eradicate the varnish which has become ingrained – this is effected by paint stripper and wire wool.

Thompson Third Corridor (TK) 1623

The seat moquette which had been damaged by ingress of water through a defective window seal has now had new material fitted in place of that which was damaged and the bench seat now awaits taking to 1623 and lifting into place.

On February 22, 30 specially made white lampshades, manufactured to the original LNER design, were collected from Suffolk Glass, Sudbury. The cost has come to over £2,000, but that is the price we pay when we strive to restore a carriage to as-built condition. Each lampshade was hand-made after which all were annealed, i.e. oven heated and then allowed to cool naturally. This process removes any stressing left in the glass.

30 pygmy bulbs – 24 volt – are being procured. All we need now to complete the compartment shoulder lights are the brass retaining rings and a spacer washer for each light.

LNER Fish Van E75169

At DC Engineering, Shildon, little remains of the Fish Van – its entire body has been removed and the residual frame rests on stands. The new headstock, fitted two years ago, has been removed to permit straightening – application of heat to cut out the hole through which the drawbar passes distorted the metal.

After shotblasting, remaining welding repairs will be undertaken and then the underframe will be spray painted. When finished, will be brought back to Pickering where the body will then be refitted. The roof is to be rebuilt with new timbers, as will the ends of the van.

LNER BTK No. 3669

The ultimate accolade – display at the National Railway Museum – now awaits this 1930-built carriage. A working party attended on February 17 to help prepare the vehicle for public display with the Flying Scotsman exhibition – this work included white painting the tyres.

It’s hard to believe that this is/was a Fish Van! Totally dismantled to the bare frame, all metalwork needing attention will now be undertaken, as well as refitting both headstocks. These are new, replacing the severely corroded original ones. Photo. Nick Stringer

The main bodywork repairs on 189’s lower roof section continues. The LNERCA’s joiner, Andrew Daniel, replaces some defective cant rail.

Another vital – and long job – on 189 entails removing all varnish. Much of it is in poor condition and ‘blown’ in many areas. By removing it all ensures a complete re-varnish can be undertaken, starting with gold size and then many coats of varnish. Regular stalwart, Doreen Williams, removes old varnish from the bottom rail. Both sides of bottom rail have now been stripped.

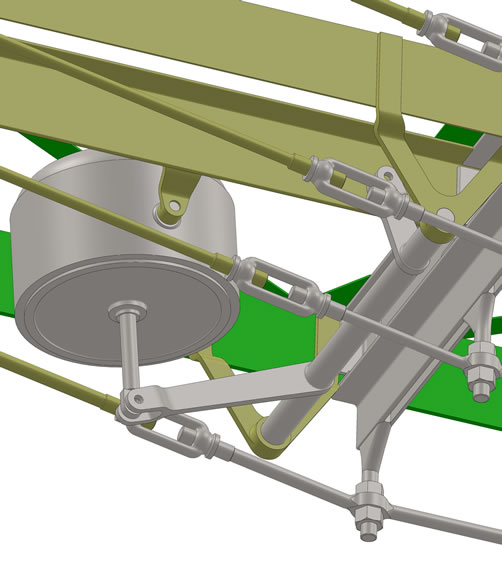

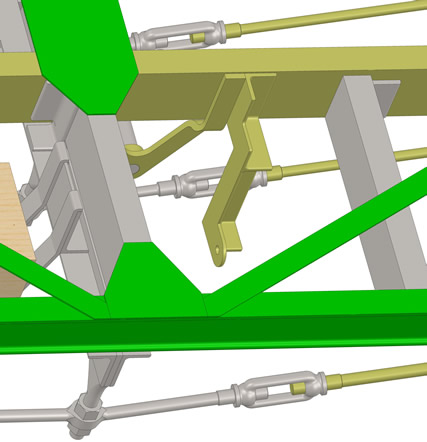

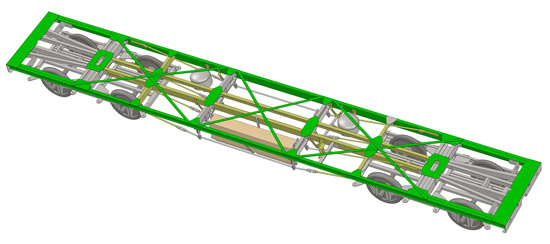

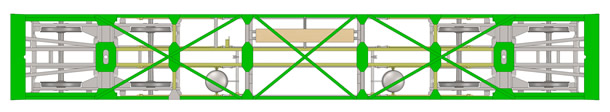

Shortening the 61’6” underframe for ECJS No. 189’s body was a far from a simple project – not just a matter of removing a chunk from the middle. Besides the trussing to consider, there was the matter of ensuring that cross members would be in the correct position. Anther consideration to determine was where the brake cylinders could be refitted. It was decided to have both of these on the same side, opposite the one battery box. To give some idea of the immense amount of planning involved, a selection of Computer Aided Drawings (CAD) are shown. These were drawn by A1 Trust Engineer, David Elliott, to whom thanks are given and for allowing them to be reproduced here.