Vintage News 2017

Humble CCT to be given TLC – Nov 2017

In a most welcome move, the LNERCA’s Covered Carriage Truck E1308 is to be given some attention. Invariably, non-passenger carrying vehicles are always at the bottom of the pile and queue for renovation as resources, both financial and manpower, are directed to more pressing and prioritised carriages.

However, there comes a time when stores vans – which play a vital role in traction and rolling stock groups activities – reach the stage where they have to be promoted, otherwise the spectre of scrapping hoves into view.

E1308 was donated to the LNERCA by Doncaster Works and it came to Pickering in July 1996. Since then it has more than earned its keep as a stores vehicle.

The LNERCA is grateful to Kieran Murray, NYMR C&W Manager, for allowing E1308 into Pickering yard for repairs to start. It will reside in the yard for one month, during which time as much of the bodywork will be renewed. The double doors are to be rebuilt, and whilst they are off the van, the gaps will be filled by temporary plywood. Six-foot sections of the bodywork will be dealt with at a time. This will entail moving stores inside to alternative positions to allow access to the framing and defective woodwork.

If good progress can be made, it may be possible for E1308 to be brought back into the yard next year to be completed. A new roof canvas would be desirable after all these years in the weather and a repaint – likely in LNER Brown – will also eventually be given.

LNER-designed Fish Van E 75169

Concomitant with the news on E1308, is it pleasing to report that another of the LNERCA’s non-passenger-carrying vehicles is also progressing. A set of components to allow the overhaul of the vacuum brake cylinder was ordered at the end of October. This is all part of pushing along the renovation of everything below the frame. A start on the wooden framing is due to start next spring when our contractor has a window of opportunity.

ECJS Restaurant Third No. 189

The big news on No. 189 is that the two partitions have been re-erected in the saloon, breaking up the long saloon into three sections. This has been a noteworthy, visible progress. The two partitions also hold up the clerestory roof and are mounted on the floor, resting on specially laid cross-body beams. Hitherto when we obtained No. 189, these beams were not in place.

Approximately 80% of the new windows and retaining wooden beading surrounds in the raised clerestory roof section have been installed.

Re-varnishing taking place

It is so pleasing to record that Gresley TTO 56856 is now in the C&W paint shop and is being revarnshed. This is long overdue – but this is no reflection on the beleaguered C&W workforce – depleted by staffing numbers and a colossal workload. Because of the time elapsed since last revarnished, much of the varnish has ‘blown’, with patches exposed to bare wood. This has necessitated sanding all the body down to bare wood to start again. It is not known how many coats of varnish are to be applied – when built, Doncaster Works used to apply a large number – in excess of ten!

We have been told that the other TTO, 23956, is also be given the same treatment, which means that by next season, there will be two pristine-looking Gresleys for the public to view and savour, hopefully both also sporting new white roof coatings to boot.

More histories

Another carriage history has been added to the LNERCA website. This is for buffet Car (RB) 641. To see its life and times, after typing in www.lnerca.org, click on ‘Vehicle Histories’ at the top of the page, and you will then see at the bottom of the ‘Vehicle Histories’ page banners with the various carriages for which histories have been documented. Click on the banner for Restaurant Buffet No. 641.

The first new section of vertical boarding has been fitted to CCT No. 1308. The CCT is likely to be externally painted in LNER brown.

A new section of teak rail is compressed into position by Marcus Woodcock. The door runner will be fitted on top. All six doors are to be rebuilt during the winter months.

Derek Gibson undertakes painting of boards for use on the CCT. The wood is first painted in Aluminium primer, followed by grey undercoat.

Major visible progress is seen inside No. 189 with the erection of the two partitions, breaking up the interior into three distinct sections. These also support the clerestory.

First look at a completed armrest for TK 1623 showing the newly fabricated and painted 6-holed bracket. The originals had three holes – which proved insufficient.

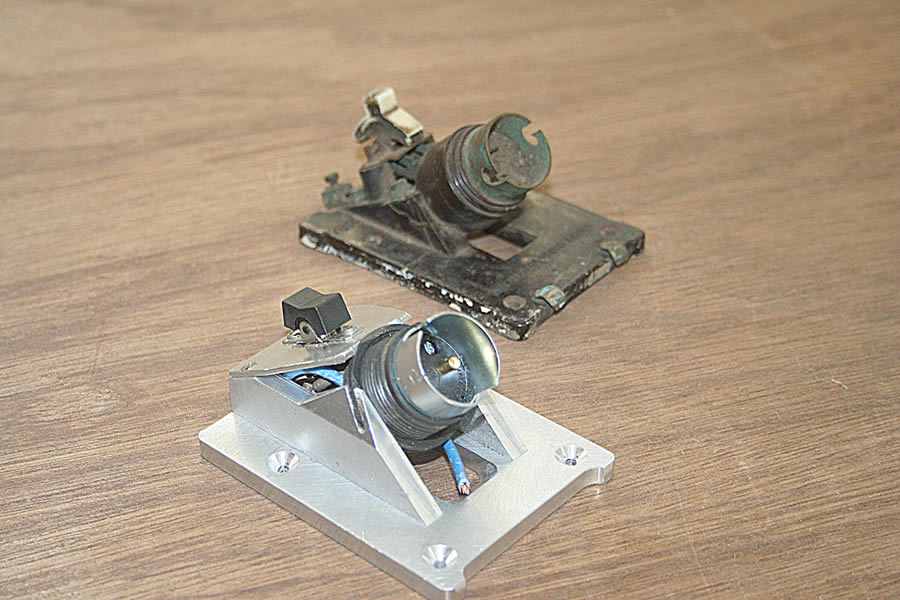

The first trial sample of a new toggle switch for use in TK 1623 to replace all those wrecked by the vandals. One of the former originals is seen alongside.

Surprise revelation with the Fish Van – Oct 2017

The opportunity has been taken, at long last, to accurately measure the Fish Van’s tyres.

It had long been thought that they were below scrap size and that the only way E 75169 would be allowed to run would be to obtain replacement wheelsets. Not so. The measuring revealed the complete opposite. On all four wheels, the flange height and thickness were well above the minimum requirements. The wheel profile itself, again on all four wheels, was really excellent, indicating that turning on a lathe was definitely not required.

In fact, the engineer’s findings show that not only would the Fish Van meet all the parameters for use on the NYMR, there was no reason why, when fully restored and all compliance issues had been addressed, that the Fish Van could travel to Whitby on a passenger service.

Should this eventually happen, it would be a really significant event. Not only would it recreate a time-honoured aspect of passenger trains in this area, but would be a notable ‘first’ in the preservation sector as no other heritage four-wheeled non-passenger vehicles run on the national network.

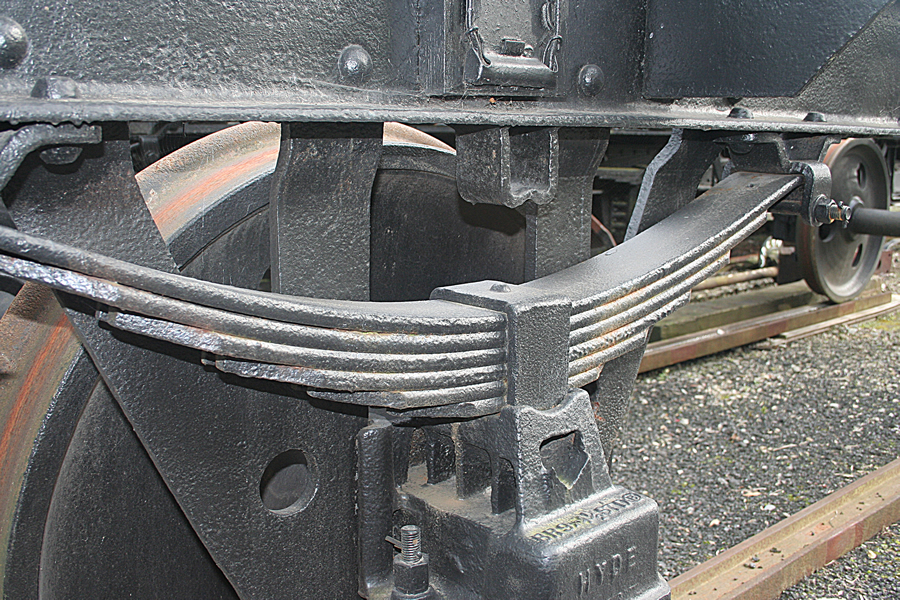

Meanwhile, the eight M20 bolts have been ordered to allow the refitting of the brake gear hangers. It is now the intention to remove the four springs and send them to Owen Springs Ltd., Rotherham, to ascertain condition, i.e. whether they need total replacement or merely re-tempering.

Thompson TK No. 1623

All 28 larger armrest brackets have now been fabricated and painted, ready to have the armrests refitted to the seven compartments of TK 1623.

ECJS Restaurant Third No. 189

The fitting of the clerestory window glass and its associated beading on the outside – and sealant – continues. Most of the carriage has now been completed and thoughts will turn to fitting the remaining roof boards on the lower part of the roof below the clerestory.

Inside on the floor, where the two partitions will be located, two wooden beams/supports have been fitted onto the framing. These will support the partitions which, in turn, will support the clerestory roof. It is thought that the lack of these floor supports might well have contributed to the sagging of the clerestory roof when we took delivery of No. 189.

More histories

Two more histories have been added to the LNERCA website. These are for North Eastern Railway LC No. 1111 (at Levisham) and LNER TTO 43632. This latter vehicle is the odd-one-out because it is the only Gresley carriage on the NYMR which is not under the umbrella of the LNERCA. However, for the sake of completeness, its history has been included. To see these latest life chronicles, click on ‘Vehicle Histories’ on the top of the home page and you will then see all the rolling stock for which known histories have been researched. Click on the relevant one you wish to see.

Using a calibrated gauge, all four Fish Van wheels meet the criteria for running – flange height and thickness, together with the profile. The door opens to the possibility of running this Fish Van to Whitby once rebuilt and all standards set by Network Rail are met. Although we have no definite proof, it is believed E75169 was one of the last such vans to have worked from Whitby in 1964.

The four springs on E75169 are shortly to be removed for assessing for further use. These will be sent to Owens at Rotherham where they will be dismantled and each leaf inspected. On the face of it, the springs appear in good order but only a strip-down will confirm actual condition.

The long and tedious job of sanding down the framing on ECJS 189 continues, come the day panelling can be refitted. When using glue blocks to hold the external teak panels on, it is vital that all remains of paint and other detritus is removed so that there is wood to wood contact. Here, the sanding block is being wielded by Dave Young.

On the floor of No. 189, two lengths of teak have been inserted as pictured here. These will support the two partitions which split the saloon area into three sections. The partitions in turn, help support the roof. It is believed that their non-inclusion previously contributed towards one of the reasons why the roof was sagging when the LNERCA took ownership of this carriage

Water is the arch enemy of carriage restorers. With the installation of the clerestory lights (glass) and the fitting of the beading, sealant is applied to ensure no water can enter. This is the job Nick Smith is undertaking. The beading itself is to be treated with a modern water-repellent coating before being painted.

LNER set back in traffic – Sept 2017

After a herculean effort by staff and volunteers, a six-coach LNER set was returned to traffic on August 12. A vast amount of work was necessary and the LNERCA would like to thank everyone who gave a hand.

There has been a tremendous repose from members, the public, and companies offering help – this is really most appreciated.

£42,000 was donated – a staggering sum. If any money is left over after replacement items have been procured and fitted, any surplus will go towards the renovation of the Buffet Car – No. 641.

With six in service (excluding RB 641 and BTO 43567 – which is in the Pullman rake), Some of the carriages have replacement and temporary fittings, pending acquisition of correct patterns.

In the case of TK 1623, smashed light fittings have been removed and wires taped over – these will take many weeks to procure as previously all these components had to be specially made. It is probable that the lampshades will, this time, be made in white plastic.

The buffet Car 641 is overdue major attention, so the opportunity is being taken to undertake these large jobs and repair the damage at the same time. For this, No. 641 is to be sent away to a nominated contractor and options are being evaluated.

The main work involves the replacement of the rack plates – metal plating above the bogies for which the body needs to be lifted. Some springs need changing and there is a host of other jobs, some vital and others which would be ‘nice to have’.

One item on which the owner is rightly insisting relates to the repair and overhaul of the Stills boiler. This will allow, once again, hot drinks, including real coffee, to be served – not in plastic cups but proper crockery. After all, this is a Historical Railway Trust!

641 will therefore not be in service this year.

Fish Van E75169

The brake cylinder has now been dismantled and new parts are being ordered in the next few days.

DC Engineering, Shildon, is to return to Pickering in the near future to attend to some welding jobs which were left uncompleted when the chassis was at Shildon.

8 x M20 bolts are being ordered which will allow a start to be made on fitting the droppers (which hold the brake blocks in situ).

New pipe, which will form the through vacuum pipe, is also to be ordered.

In essence, completion of all the underframe equipment is being progressed.

No contact has been made by the Transport Trust – the LNERCA has made an application to be considered for one of the TT’s annual awards towards completing vehicles under restoration.

ECJS Restaurant Third No. 189

Most visible is the progress relating to fitting the widened teak panels which are being inserted between the windows. These have all had an extra piece of teak expertly glued onto the original, the object of which was to make them wide enough to be covered at the edges by the beading. Previously, because these teak panels were not wide enough, the beading barely covered the edges.

Also worthy of note, all the wooden framings which hold the clerestory glass have been fettled and painted white. New glass has been procured and installation of these windows will now be taking place. Before these are fitted, a transparent plastic film is applied to prevent splinters in the event of breakages.

NER TO No. 945

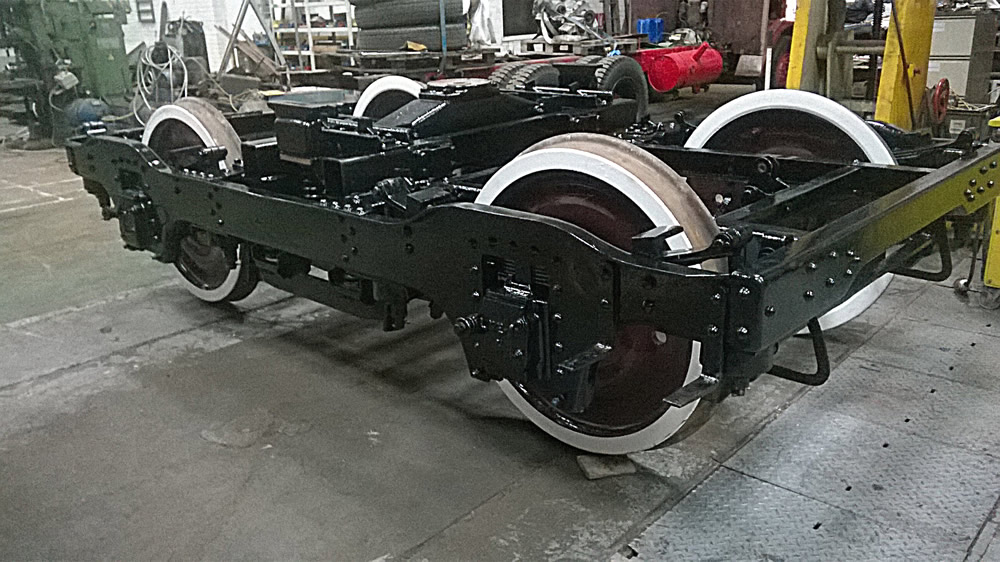

The two LNERCA-owned Gresley bogies have been overhauled by DC Engineering at Shildon. These are due to go under the North Eastern Railway Coach Group’s No. 945 in due course.

Thompson TK No. 1623

Investigations are underway as to how best to obtain replacement shoulder light fittings, smashed by the vandals. It is likely the toggle switches will, this time, be manufactured by CNC technology using aluminium.

The long job of making 28 larger (than those previously fitted) brackets which hold the armrests onto the sides of each compartment in 1623 has been started. Each of these brackets has 6 screw holes facing the compartment wall – enough, we hope, to ensure they stay tight and remain tight.

LNERCA workshop

Nearing completion, the workshop sited at the north end of the yard next to High Mill level crossing has lost its grey undercoat and now sports two-tone ‘livery’ of green and an interesting shade of light stone. Anyway, it looks a vast improvement on what masqueraded before. Top marks to the junior volunteers who came in force, wielding paintbrushes. Some finishing touches were made by members during the ‘Coach Week’ at the end of August.

Nick Smith rollers out the air bubbles from the protective transparent film on top of the glass – this will be inserted in the vertical sides of the raised roof section – the clerestory.

This picture illustrates the repainting framing being installed into the clerestory section of No. 189. Then the glass will be fitted. The arm belongs to Gary Lyne.

Sorting out the myriad of screws – a necessary and vital task pending fitting of the internal window framings is Malcolm Brown. This Tyneside gentleman has become the resident tour guide for visitors who venture into the Atkins shed.

A close-up of a widened teak panel which is now adequately covered by the beading on each side – previously, the beading barely covered the panel. This has taken quite a time and has been done so expertly, you can hardly see the join.

With the widened panels now going in, the coach body begins to look less derelict and more like a carriage. It also illustrates just how much work is going into the body – all being undertaken to an exceptionally high standard. Below the panels can be seen the new waist rail which runs alongside the whole length of the carriage.

Here is one of the new brackets being made to fit the armrests into Thompson TK No. 1623. The new bracket features six holes – previously there were three – and it is hoped these will be enough to secure the armrest tightly in position. Six completed, 22 more to finish.

This was almost a picture caption contest. Braving the Long Siding Rain Forest are Messrs Stringer, Cullingworth and Woodcock. Their mission, as they had chosen to accept it, was to fight their way through the jungle to a spare Gresley bogie in order to recover three springs to be used to complete the overhaul of two Gresley bogies at DC Engineering, Shildon, which are destined to go under NER Open Third No. 945.

This is one of two Gresley bogies completed by DC Engineering, Shildon, destined to go under NER TO No. 945. However, they might temporarily go under ECJS No. 189. The second bogie is virtually complete – just awaiting three springs recovered from the dense undergrowth at the Long Siding, Pickering. Picture: Nick Stringer.

Assessment made of vandal damage to the LNER set – 25th July 2017

Following the attack on the stabled LNER set which was parked in the ‘short end neck’ adjacent to High Mill crossing at Pickering on Saturday night/Sunday morning – July 22/23, a more thorough assessment was made today of the damage inflicted by the vandals.

The gratuitous violence inflicted on the carriages could have been worse, but, nevertheless, it is going to take weeks to repair. For some of the carriages, only the light bulbs were smashed but for others, it will inevitably be some time before those carriages can see public service again.

A resume of all seven carriages involved is shown below with relevant comments:

GN saloon No. 43087 –

Net in luggage rack 2 off

Bulb 1 off

Ryedale Restaurant Car No. 43654 –

South west Droplight

Bulbs 8 off

Lamp shades 7 off

Light fittings 4 off

Buffet Car No. 641 –

Main windows 6 off

Ceiling lights 9 off

Tea urn

Table

Bellows (North and South)

Tourist Third Open No. 56856 – this is the TTO with the LNER ‘bucket’ seats.

Ceiling bulbs 6 off

Side bulbs 2 off

Ventilator 1 off

Seat ripped (seats no. 32, 42, 44 and 50)

Door handle

South bellows

Tourist Third Open No. 23956 – the TTO with the later straight-sided seats is owned by the National Railway Museum and officials at the NRM have already been contacted with the news.

Ceiling lights 11 off

Side lamps 7 off

Mirror

Thompson Third Corridor No. 1623 –

Lamp shades 20 off

Bulbs 21 off

Light fittings 22 off

Mirror 2 off

One seat ripped

Coat hanger

The procuring and fitting of the shoulder lights in the seven compartments was the most time-consuming task of the whole restoration, taking over a whole year to source the parts (7 in total) including the lampshades. We know that one of the suppliers is no longer in business so we can say with some certainty that No. 1623 will take the longest to repair.

Brake Third Corridor No. 3669 –

Shades 4 off

Light fitting 1 off

Bulbs 3 off

Drop light 1 off

1 Paraffin tail lamp

The light fittings were kindly supplied by the Severn Valley Railway.

Full set possible wiring damage

Full set possible fabric and lino damage don’t know until first pass of cleaning the coaches

Finally, all the fire extinguishers were let off along the seven-coach with the resultant spray going on the moquette, all of which will require a deep clean. This latter will also be necessary in view of the ‘bodily fluids’ left by the perpetrators.

The LNER Coach Association will be making a ‘Victim Statement’ to be given to the police in due course – this will include all damaged items, the work needed to put right this damage, the cost, the distress caused to the restorers and the paid staff, and how many man-hours the repairs will take. The NYMR will, itself, be making a similar document available, advising the time its paid staff will have to spend remedying what they can and the resultant loss of business this act of vandalism has caused.

LNER carriages trashed by vandals – 23rd July 2017

We have the very sad duty to report that the set of LNER carriages was severley vandalised during the night of Saturday/Sunday 22/23 July. The set was stabled in what is called the ‘short end neck’ which is the siding with bufferstops right against the Hill Mill crossing at Pickering to the north of the station. Intruders, believed to be local miscreants, gained entry and started a smashing rampage.

The Buffet Car No. 641 was one of the worst affected, with every window broken and the tubular chromed chairs strewn about. Throughout the set, all light fittings were smashed and fire extinguishers let off. The vandals left a trail of damage.

It was the NYMR cleaners who came across the destruction when they entered the set to clean it for the day’s service. They found a number of the culprits asleep in the Thompson Third 1623 which had its light fittings wrecked – these took months to procure and were all specially made.

The cleaners immediately called the General Manager and the police were hurriedly summoned. The police declared it a crime scene and no-one was let in. Needles were found amid the debris. Bodily fluids were encountered and one of the perpetrators had cut himself as blood was seen. Alcohol was everywhere and confectionery, stolen from the Buffet Car, was thrown around the floor.

It was later heard that several of these vandals had been apprehended. Somewhat incredulously, these vandals had even posted images of themselves on social media which will be used as evidence.

There are many thousands of pounds worth of damage and the C&W staff and volunteers now have the heart-breaking job to try and repair the damaged set – this will take many weeks. The General Manager thought the set would not return to service this season.

There have been many messages of condolences and support from all over the country and offers of donations have also been received.

The LNERCA committee would like to thank everyone who has contacted over this appalling destruction and for the offers of help from many individuals – this is most appreciated.

The NYMR has started a Teak Set Appeal on its website – www.nymr.co.uk/news/heartbreak-after-vandals-attack-heritage-railway-carriages-news

Application submitted for Fish Van grant – July 2017

We have submitted an Application to the Transport Trust to be considered for one of its annual awards made towards completing a preservation project.

One of the main criteria is that the project must be on-going, with a reasonable expectation of completion date. The LNERCA ticks all the boxes.

Restoration of the Fish Van E 75169 has always been designated as a secondary activity but, with materials to hand, we can progress it, especially as it stands on its own isolated piece of ‘track’ outside the LNERCA’s workshop at High Mill level crossing. This means it is accessible.

The outstanding welding jobs to be undertaken by DC Engineering, Shildon, are . . . still outstanding. The reason is that this company is concentrating on overhauling the pair of Gresley bogies destined to go under NER No. 945Y.

Frame repairs finished on No. 189

It’s taken many months, but at long last the frame repairs have been completed on No. 189, predominantly by Marcus Woodcock who has been working his way round the carriage starting on the east side (next to the yard) and finishing on the west side (next to the car park). This has been, in the main, replacing split or broken half-pillars. New ones, produced by Andrew Daniel in his Harrogate workshop are made out of Sepele.

The next job is to fit the glass in the raised clerestory section prior to fitting the remaining roof timbers on the lower sides of the carriage. Thoughts are now turning to fitting the panels between the windows. These have been widened as those fitted were clearly of insufficient width as proved by the fact that the beading which covers the edges barely did so.

Thompson Third Corridor (TK) No. 1623

New, deeper, brackets for the armrests have been fabricated. These incorporate six holes rather than three as found in the original brackets. By having more screws holding them to the sides of the compartments, it is anticipated that passengers of a larger disposition (how nicely put eh?) will find they can use the armrests to lever themselves out of the seat without loosening or, indeed, breaking off, the armrest. Once a complete set of brackets has been made and painted teak brown (48 in total are needed), a start on refitting the armrests will ensue.

Condition of LNER set

The LNERCA committee has understandably been increasingly concerned over the external state of the LNER set. Not only are several carriages in dire need of external attention in terms of re-varnishing, but the set is now looking increasingly dirty. The reason is that it never gets the chance to be washed. It is drawn out of the Long Siding at Pickering for its two return trips, then shunted back into the Long Siding.

The LNERCA has asked the NYMR management if special arrangements can be made to have it brought into Pickering station early so that a start can be made to wash it.

In addition, it is good to report that Kieran Murray, C&W Manager, has plans to revarnish TTOs 56856 and 23956 this year.

LNERCA workshop

More progress can be reported in the re-cladding of the building. In fact, with the completion of the north end, thoughts can now turn to painting the structure – in LNER colours, green and cream.

Never a dull moment

Wood finisher and marquetry expert, Neil Cawthorne, has stumbled across a French varnish, Called Le Tonkinois with a 200-year old recipe which appears to have far more enduring properties than what we have been using in the past. He conducted a trial using old-style varnish and Le Tonkinois on two pieces of teak items, leaving them outside for 12 weeks. The result was remarkable – see picture. Looks like we may never have a dull moment again. . . .

The unique LNER-designed Fish Van No. E75169 awaits its body rebuilding, whilst sat on its isolated track at the north end of Pickering yard. Should our grant application to the Transport Trust prove successful, this will hasten the day when it runs again. The fish van traffic was an everyday sight on the Whitby-Pickering-York line in the 1950s/60s. Whilst it is non-revenue earning, what it does is to recreate the past ambience and character of today’s heritage railway.

What a difference! Take two items in teak, varnish them with different varnishes and leave outside for three months. On the left is a droplight with standard acrylic varnish, whilst on the right is some paneling varnished with Le Tonkinois. We are now suggesting to the NYMR’s C&W department that they use this French varnish in future.

New roof goes on No. 189 – May 2017

After two years of what appears to be non progress (in reality, a vast amount of repair work has been undertaken), visible progress was made during the May ‘Coach Week’ when the new roof boards were fitted to the top part of the clerestory roof of East Coast Joint Stock Restaurant Third No. 189. At long last, the carriage now looks as if its rebuild is underway.

Prior to this, the derusted and painted carlines had been fitted, as had four oak trimmers spanning the roof, the latter which had also been expertly repaired with new timber being spliced in. It is preferable to try and use the existing wood as far as is practicable. Virtually all the original roof board had serious cracks in them – hence new ones were fitted.

The work entailed laying a centre plank down first after measuring. Then boards either side was installed, tongue & groove being the type fitted.

It is good practice to clamp the boards as tightly as can be undertaken prior to the stainless steel bolts being fitted which clamp the boards to the carlines. A long clamp is stretched over the roof, exerting horizontal forces to ensure the tongue & grooves fit tightly, but even this is not enough. At the very edge, a ‘G’ clamp is also then brought into play, so ensuring the last of the roof boards is forced down onto the carline before the hole is drilled upwards through the carline and board after which the bolt is then hammered down through the roof board.

Thompson Third Corridor (TK) No. 1623

We have capitulated. Final Score: Obese passengers – 1 LNERCA – 0.

The never-ending saga of the compartment armrests reached, perhaps, its inevitable conclusion on Sunday May 7 when all 28 armrests were taken off. To be truthful, it wasn’t 28 because two had already been ripped off by passengers.

We have spent weeks ever since 1623 was launched into traffic last year trying to tighten up the armrests which were becoming loose on a daily basis. Cause? Overweight passengers, forcing themselves out of the seats using the armrests. They (the armrests, that is) just could not take the strain.

They are held in position by means of three one-inch screws – there is a right-angled bracket underneath the armrest through which the screws fit.

When the carriage was built in 1950, everyone was of slim disposition – it was just after the war and rationing was taking place. Fast forward 70 years and the world of chips has taken over.

To bring some long-overdue light-hearted relief to this dispiriting problem, various door notices were suggested, but, as you can imagine, none were printable, especially in this day of political correctness!

The solution is likely to be dismantling every armrest and fitting a new bracket, one with a deeper vertical section which abuts the compartment wall. This will have six screw holes rather than the existing three. As if we don’t have enough to do.

LNERCA workshop

One of the panned activities during the May ‘Coach Week’ was the removal of the shrunk shiplap boarding from the workshop at High Mill crossing and replacing it with new overlapping boards.

A good turnout saw major progress made, with the entire frontage replaced, together with the south end. This just leaves the north end to do.

The boards had all been pre-primed with grey paint and it was just a matter of measuring each one before they were sawn to length and then nailed into position.

When the north end is completed, the building will have its top coat of green and cream applied.

LNER Fish Van E75169

Regrettably, no more progress can be recorded, apart from one fact, namely, the eight ‘droppers’, the metal bars about one-foot long onto which the brake gear is suspended at each wheel, have been derusted, primed and painted. We are still awaiting DC Engineering, Shildon, to attend to outstanding welding aspects.

Please contribute

If you would like to help with a donation, this will be gratefully received by the LNERCA and can be directed to the vehicle of your choice. Please contact Murray Brown (murraythermint@ntlworld.com) if you would like to help. Thank you.

It’s a long carriage when you have to fit new roof board – all 51’ 6”. This was the heartening sight on May 7 when most of the roof, the top section, had been reboarded. Half way along the carriage can be seen the horizontal clamp, used to compress the roof boards as tightly as possible before they are bolted to the carlines underneath.

The bottom, lower, part of the roof will not have new boards fitted until the clerestory windows have been refitted. The apertures for these can be seen to the left of the unboarded roof section. Also on view – which will be covered from sight eventually – are the refurbished black-painted knee-irons which add support to the framing.

What an improvement: It will look even better when painted in green and cream. Attention to the LNERCA workshop was long overdue – the shrunken shiplap was letting in water.

Good weather allowed all the front and the south end to be reclad. Here, two volunteers attack the end of the building which has served us so well over the years, both as a workshop and a store.

One side of 18477’s framing completed – April 2017

Thompson CK No. 18477

From utter dereliction to a state of definite visible progress. The entire corridor side framing has been chopped out and replaced by new – and doesn’t it look superb, painted in aluminium primer. One of the NYMR drivers commented that he had come into Pickering on a train from Grosmont and looked at the derelict carriage. On his next train, on arrival the carriage had got a new side, the new framing having been lifted into place in his absence! He was astonished.

The final work – completing the ends of the carriage where the new framing is joined to the corner posts was undertaken on Tuesday April 11.

Of interest is how this is effected. Instead of the usual tenon protruding from the rail (horizontal wooden piece), the two tenons are actually separate and are first glued into the holes chiseled out of, at one end, the new framing and second, the corner post. The final rail, about a foot long, has slots cut out to match where the tens go, is then slotted over the tenons and knocked down until the tenons are totally covered – see photographs. The new ‘West’ glue is used in the process and then the whole assembly is then screwed tight.

On Sunday, April 9, three volunteers removed all the external panelling to reveal the compartment side framing. Much of this panelling was plywood, having been installed in the 1970s by the York Area Group.

A thorough survey was then conducted on the following Tuesday by Andrew Daniel to assess the extent of work required, once the next tranche of funding has been secured.

The compartment side of 18477 is certainly in superior condition to that of the corridor side, although there will be extensive parts needing total replacing. Besides sections of the actual framing, some of the internal partitions are in a bad way, as is the roof. Surprisingly, however, parts of the carriage have survived remarkably well, for instance some laminate ceiling panels are intact in places and the vestibule ceiling and toilet panelling is intact. These will be removed carefully in due course to gain access to the framing and roof. The carriage is now sheeted over and will be placed in the Long Siding at Pickering pending the provision of further funds.

LNER Fish Van E75169

All seven carlines have been renovated, this comprising wire-brushing, green anti-oxide paint, grey undercoat and black top coat. The carlines cannot be installed until the wooden framing is in place.

And herein lies the next problem. Our joiner contractor is committed elsewhere for some months, so the decision has been made to concentrate on the underframe equipment – overhauling the brake cylinder and fitting the brake rigging.

ECJS Restaurant Third No. 189

The end is finally in sight as regards fitting replacement half-pillars. Only two more were left to fit on the west side (car park) side of 189. The reason why numerous ones needed renewing was simply one of condition – many were severely cracked and more than one was actually broken.

More carlines have been fully renovated – de-rusted, green anti-oxide paint, grey undercoat and black top coat. These are being screwed into place on the clerestory roof as they are completed.

Meanwhile at Shildon, the best brains in the north-east are trying to work out what is the best solution for the Fox bogies recovered from a crane runner in Essex.

The Coach Week in May is likely to see the new roof boards being installed. Other planned work for the Coach Week is further replacing of the shiplap on the LNERCA’s workshop at High Mill crossing.

GNR saloon 43087

Water ingress at the observation end has caused considerable damage. Mike Illingworth is exercising his considerable joinery skills and has cut out much damaged wood, replacing it with new hardwood. Parts receiving attention are the vertical half pillars below the main window and some of the end beam which sits across the width of the vehicle. With the external teak panels split at the end of the carriage, below the window, new panels will be required unless the existing ones are capable of being glued.

Please contribute

We often find in the restoration business that folk, in many instances, have a favourite vehicle and because of these ‘leanings’ may well consider contributing towards their renovation. May we seek your generosity by sending a donation for the vehicle of your choice to aid its completion? These are the Fish Van E 75169, East Coast Joint Stock No. 189, Thompson CK 18477 or the overhaul of the Fox bogies. All monies received will be guaranteed to go direct towards these respective projects. Please contact Murray Brown (murraythermint@ntlworld.com) if you would like to help. Thank you.

Now you don’t see it, now you do. After the views of the dereliction and the whole corridor side ripped out, here is the heartening sight of the new framing in place. Assembled in the Atkins shed, each of the three sections was carried out into the yard and then lifted into place after preparatory work by the LNERCA’s joiner, Andrew Daniel. The C&W staff are readily acknowledged for their kind assistance in lifting the sections out of the shed and to Kieran Murray for operating the Teleporter which hoisted the sections into place.

Andrew Daniel illustrates the fascinating technique for adding the final rails into the gaps at each end of the carriage – between the brand new framing and the original corner post. First of all the separate tenons are glued and knocked into the prepared holes.

Secondly, the piece of rail (hardwood) is then placed over protruding tenons and gently pushed down over the tenons until they are fully covered, They have been glued beforehand.

Once the rail is fully in its correct place, four stainless steel screws are then inserted through both ends of the rail and through the now encased tenons.

There are three such rails to be inserted at each end of the coach. The joiner has inserted two, leaving the third which is at the top of the coach. As it sits just below the cant rail, once the tenons are glued into place, this third rail is knocked upwards to encase the tenons, unlike the two rails lower down.

On the other side of 18477, three volunteers set to on April 9 to remove all the outside cladding – or what was left of it. Much of this was plywood, having been fitted in the 1970s by the York Area Group. Andy Pollard takes a break to look at what’s underneath the removed plywood. Whilst parts of the framing and partitions are somewhat grim, generally, the west side of the carriage is in far better condition than the east side. The cladding was removed in order for a thorough survey to be undertaken.

Repairs to the GNR saloon have been taking place. Water ingress has caused considerable rot and a considerable quantity of wood has been removed. Mike Illingworth has been effecting repairs. In this view, the extent of the new wood can ben seen, especially on the floor. Of interest are the two vertical grey half-pillars. As Eric Morecambe would have said – you can’t see the join. The bottom half of each half-pillar has been replaced by new, being fitted by means of a barely discernable scarf joint.

Removal and replacement of wood invariably necessitates dismantling of other components. Mike Illingworth cleans out the recess in the bottom end beam with a chisel in which sits the strangely shaped knee-iron (which adds strength to the framing). The knee-iron can be seen next to the brush. The LNERCA is kindly helping out the NYMR paid staff in repairing the GNR saloon because of the workload of the C&W department with the backlog of Mk.1 carriage repairs.

Found! Long ‘lost’ Fox bogies – March 2017

We have managed to find a pair of 100-year-old Fox bogies and, even better, the owner has agreed to allow us to swap them for a pair of our Gresley-designed bogies. The Fox bogies will go under ECJS No. 189 – it was built with them in 1894.

It was the LNERCA’s Archivist, John Sutcliffe, who spotted them in a photograph. They were sitting under a crane runner on the Colne Valley Railway in Essex.

A visit to this Essex outpost duly confirmed the remarkable ‘find’ – buried in brambles and weeds. The crane and its runner (on which the jib rests) had not moved for over ten to fifteen years.

The owner, Martin Nixon, was known to Murray Brown, so inquiries were made. He willingly said “yes”.

However, the sheer logistics of getting these bogies warrants a book being written.

The first problem was to how to raise the jib off the runner. The NYMR’s C&W fitter, now C&W Manager, Kieran Murray also paid a visit and soon came to the conclusion that using jacks was not practicable or safe because once the jib was raised, the area sitting on the jack top decreased as the jib moved upwards in an arc.

It was looking grim. Then a chance meeting with the Jeremy Dunn, leader of the 45163 restoration group, in an adjoining building revealed he knew a lot about the crane’s history and, better still, offered to try and raise the jib using compressed air from his workshop. So, after Christmas, a trial was undertaken – it worked, and the job was locked in the raised poisitio0n. This meant that the runner could be uncoupled from the crane.

We now needed the Colne Valley Railway to move the vehicles away from the runner so it could be extracted and placed on the departure road ready for collection by road transporter.

The CVR’s General Manager, Paul Lemon kindly undertook this large shunt and runner DE 320878 was ready for collection. DE 320878 was originally a GNR non-corridor carriage.

The plan was for DC Engineering to collect the runner, transport it to their Shildon workshop, replace the bogies with those of Gresley type. This took place on March 14 and an assessment is being made on the vintage Fox bogies prior to renovation. The runner will be returned to Castle Hedingham, CVR in due course.

The LNERCA is indebted to Martin Nixon, Jeremy Dunn and Paul Lemon without whom this extraordinary saga could not have reached fruition.

LNER Fish Van E75169

The first carlines which span the sides and onto which are screwed the roof boards have been refurbished. They are being wire-brushed, primed, undercoated and top coated. These carlines are in excellent condition, bearing in mind their age (69 years old) one reason for which is that they were previously painted in a bitumastic black paint which has clearly protected the metalwork.

ECJS Restaurant Third No. 189

It is great to know that we can now restore No. 189 to as-built condition with the acquisition of a pair of Fox bogies.

We now need another pair to put under NER FO 2118, but we may not be as fortunate.

The other news is that David Elliott has supplied us with new computer drawings of the shortened underframe – these are required to show the exact location of the brake cylinders and whether such positioning would impinge on frame members.

Gordon Wells has been making new battery cases – these will fit inside a battery box on the underframe, or do we hide them inside a replica gas tank?

Meanwhile, in the Atkins shed, work has progressed on refurbishing the carlines – derusting and repainting. In addition, where they are screwed to the top of the cant rail, rotten wood found underneath where they sit has been chopped out and sound wood inserted.

Neil Cawthorne has made good progress on sanding down many of the doors and paneling, making good defective joints where found.

More half pillars have been inserted into the framing and volunteers have been gradually moving along all the original half pillars, sanding off the gunge and glue down to bare wood. This is a prerequisite for fitting the teak panels using new glue blocks. The glue blocks are stuck to the internal face of the teak panel and another side of the glue block is stuck to the frame – hence bare wood is needed as there is no point trying to stick the glue blocks to paint or old glue.

We have found enough brass components on the body to make the saloon (uplight?) windows work, however we are missing the brass catches which hold the window shut against the springs which lift the windows. We think these may be an American Pullman fitting but have never seen any examples, they will have been a proprietary off the shelf fitting if any reader has one or knows of a modern supplier please contact us.

Thompson CK No. 18477

The remainder of the corridor-side new framing has been machined in Harrogate, transported to Pickering and assembled in the Atkins shed. Once the C&W can find space for 18477 to be moved into Pickering yard, the framing can then be lifted into place by the LNERCA’s joiner, Andrew Daniel.

Worth a mention

Two carriages have been receiving the attention of Mike Illingworth – another craftsman with a penchant for woodwork. BTK No. 3669 is having attention to a door pillar where the lock fits. This had become damaged, we think due to incorrect use of the door mechanism which duly split the wood.

Mike has also started dismantling the end of Jim Kay’s GNR (LNER) saloon 43087. Water has been getting in over the collision pillars and a strip down is required to assess what repairs are necessary.

Several volunteers have been making inroads into painting boards with aluminium primer – these are destined to be fitted to the LNERCA’s workshop at High Mill at the end of Pickering yard. Later this year, the old shiplap will be ripped off and the new boards fitted. When finally complete, the building will be painted in the LNER’s green and cream.

Invitation

The LNERCA welcomes any assistance readers can make, either financially or physically. Donations are welcome towards any of the vehicles under restoration or the special appeal to renovate the LNERCA-owned Gresley bogies which will go under NER 945Y. Please contact (marcus.woodcock@yorkscoast.plus.com) or Murray Brown (murraythermint@ntlworld.com) if you can contribute or, better still, lend a hand.

An amazing find – a pair of Fox bogies. They were covered in dense undergrowth in a siding at Castle Hedingham, Colne Valley Railway. This picture was only possible once much gardening had been undertaken.

With the runner detached and shunted out of the siding, it stands in the departure line awaiting collection by the road transporter to take it to Shildon where the bogies will be swapped. Photo. Jeremy Dunn.

To whet the appetite as to things to come – he is an internal view of NER 945Y. The LNERCA is now helping the North Eastern Railway Coach Group to speed up its completion by providing two overhauled Gresley bogies. Other work will include provision of gangways, bellows and recanvassing the roof. Photo. Peter Brumby

A time-consuming task – Andy Cox sands down the half-pillars of No. 189 in order that when the triangular glue blocks are fitted, the face which glues to the framing is literally wood to wood rather than trying to glue the block to old glue and residual gunge.

Gordon Wells has been busy making new battery boxes for No. 189. They will sit on one side of the underframe. The brake cylinders will sit opposite the battery boxes on the other side.

Impressive! This is the remainder of the new corridor-side framing destined for fitting to CK No. 18477. It was machined in Andrew Daniel’s Harrogate workshop, then moved to Pickering for assembling.

Mike Illingworth has been repairing the door pillar on one of the compartments of Gresley BTK No. 3669. Mis-use of the door mechanism resulted in the wood being split. The damaged teak is shown in the first picture having been cut away, whilst the second image shows the new piece of teak ready to be glued in.

An appealing appeal – Feb 2017

With the most welcome news that the LNERCA is taking the North Eastern Railway Coach Group’s unique Open Third 945Y under its wing as an affiliated carriage, this opens the door to aiding its completion – and that’s exactly the plan. To this end, the LNERCA is providing an overhauled pair of Gresley bogies to be placed under 945Y when the carriage enters the Atkins restoration shed, Pickering, once ECJS 189 is watertight and can be placed outside.

The bogies will remain the property of the LNERCA but will make a huge difference to the completion date of this beautiful NER carriage.

With funds in short supply as virtually all monies raised are going towards 189, the LNERCA is seeking donations from members and readers who have an interest in carriages, and, in particular, unique NER carriages.

If you feel you would like to help push this carriage forward towards the day it makes its inaugural run, do please send a cheque however, small, however large, to the LNERCA’s Treasurer, John Hasler, 103 Bramley Garth, Appletree Village, York. YO31 0PQ

LNER Fish Van E75169

Having received quotations for the new wood for the framing, an order is expected to be placed shortly.

Work is to start imminently on refurbishing the carlines (hoopsticks) which space from side to side and onto which are bolted the roof boards.

It is clearly evident that the van has been extensively rebuilt during its previous life as the hoopsticks have somewhat rudimentary pieces of wood bolted to their sides in short lengths, these forming a crude arc across the van. All of these are being removed and will be replaced by something more professional.

ECJS Restaurant Third No. 189

All of the east side framing has been completed and work continues on the west side (car park side).

Attention is now turning to the teak paneling between the windows above the waist rail. In many cases, this, simply, is not wide enough, the two-inch flat beading which runs down each side is barely covering the teak panel, i.e. holding it in place. It is blatantly obvious that the teak panels are not wide enough because the tell-tale recess into which they fit can still be seen. Strange they were refitted like this in the first place?

Thompson CK No. 18477

More brand new framing has been produced by Andrew Daniel and fitted along the corridor side. The plan is to complete the whole of the corridor side pending raising of more funds to tackle the next stage of restoration.

Do help

If you are getting under your good lady’s feet, then why not escape and have an enjoyable time with the carriage volunteers in the heated Atkins shed where good banter and fulfilment are the order of the day. However, for those ladies jumping up and down at that politically incorrect remark, our invitation also extends to ladies who are getting under husbands’ feet or are fed up of talk of football and golf. Please contact (marcus.woodcock@yorkscoast.plus.com) or Murray Brown (murraythermint@ntlworld.com) if you can come along.

These are the two LNERCA-owned Gresley bogies under overhaul at DC Engineering, Shildon, which are destined to go under Open Third No. 945Y. Your donation to help finish them will be much welcomed.